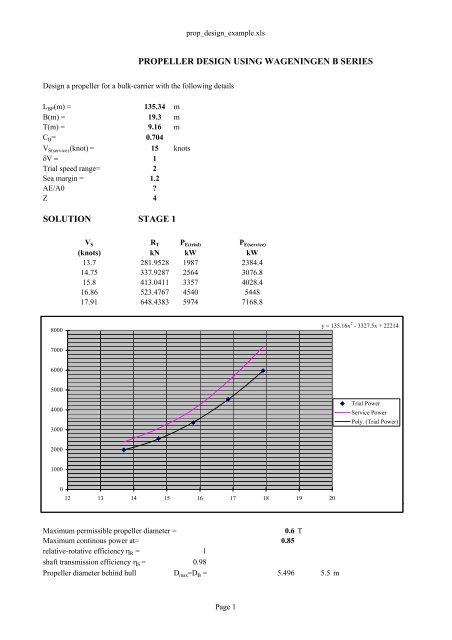

Theoretical required prop pitch in inches. Design a propeller for a bulk-carrier with the following details.

Step 4 Propeller Selection The Uav Chronicles

Hello Im ready to do Propeller Design Spreadsheet module and complete within 48 hours deadline I have good knowledge and experience in this field.

. V V U A 2 2 rn - T 2 2 2 13. L BP m 13534 m. Required prop pitch for top speed.

The stresses referred to are principal stresses. Aircraft propeller design calculation spreadsheet pdf file download online Nearly all unemployment agencies accept claims online especially in light of the COVID-19 pandemic. This Master thesis will be focused on the design procedure of a marine propeller for 800 TEUs containership in order to find the optimum propeller.

B m 193 m. They are not intended to perform complex cavitation or efficiency calculations. Free to use Propeller Sizing Calculators.

While designing a propeller various factors should be kept in mind so as to design a very efficient propeller. Welcome to the Surfbaud Freeware Propeller Calculator for Excel. Estimated prop slip at required top speed.

In certain cases such as naval propellers the purchasers of the propeller may. UTmean UAmean Cxzbi Goldstein factor from diagram blades UT UA VA n Hz Lift Nm CL Rn Blade section lift coefficient Dimless radius. Trial speed range 2.

KEY This spreadsheet is freeware. CD 2CF 1 2 c 2 16. The results provide best size propeller dimensions based on your input data.

Calculate the resulting total velocity at each radius. The following are the factors that help in improving the propeller efficiency. For general propeller design work the ISO specifications usually serve as the criteria for assessment.

Propeller design calculation Diam kinvisk n pa pv rho_s z r k m a Vs knots T kN RPM D m w c xx G Circulation distribution parameters. V S service knot 15 knots. All units used are imperial.

A low shaft speed given diameter is. No charge may made for using it. Calculation of marine propellers DNV GL AS SECTION 2 CALCULATION OF HIGH CYCLE STRESSES IN PROPELLER BLADES 1 High cycle stress criterion Dynamic stress amplitudes in the propeller blade shall fulfil the following criterion.

The choice of an optimum marine propeller is an important issue in Naval Architecture. V V U A 2 2 rn - T 2 2 2 13. Calculate the lift of each section.

The propeller design calculation consists of three steps. ISO 484-1 2015 and ISO 484-2 2015 which now supersede the earlier 1981 standards define the requirements for propellers greater than 25 m and between 080 and 25 m respectively. Calculate the drag coefficient of each section.

Now to complicate matters static thrust is proportional to the exit velocity squared so in this example the 2-bladed prop would produce 142 196x as much thrust as the 1-bladed prop the 3-bladed prop would produce 162 256x as much thrust and the 4-bladed prop would produce 172 289x as much thrust. The propeller design is an activity which nowadays presents ever increasing challenges to the designer. Up to 24 cash back Agitator Design Mech Spreadsheet.

Propeller Design in the Mission Simulation Program 39 52. I have extracted three pitch angles from the graph above. Anchor Propeller Pitched Blade Turbine Chemineer HE-3 Hydrofoil Sawtooth Curved Blade Turbine Straight Blade Turbine Disk Turbine.

Lets calculate the advance ratio at an engine speed of 4300 RPM and a propeller diameter of 170 m approximately 57 inches with the aircraft flying at 120 knots. 20 25 and 30. Propeller design calculation Diam kinvisk n pa pv rho_s z r k m a Vs knots T kN RPM D m w c xx G Circulation distribution parameters.

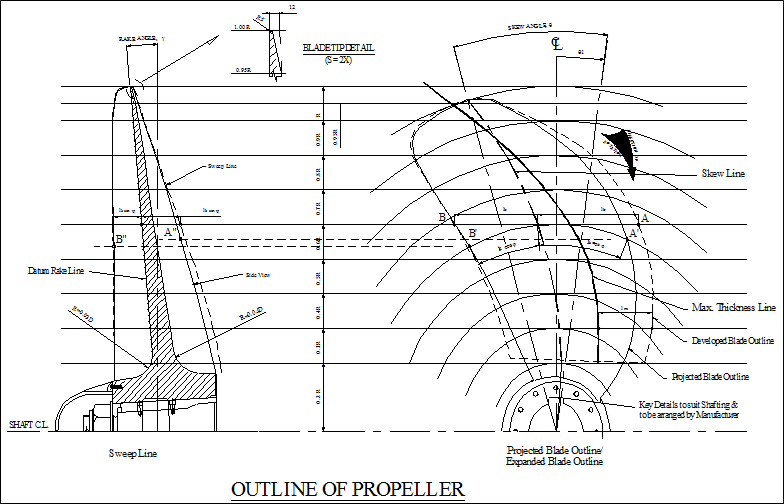

Design of propeller turbines for pico hydro. The propeller shaft is geared down by a ratio of 227. Determination of camber and pitch distribution Calculation of thrust and torque 1.

Before you start we would like to point out that these calculators are based on empirical data. PROPELLER DESIGN USING WAGENINGEN B SERIES. T m 916 m.

It is observed that the speed of the shaft and the propeller diameter are very closely related. C B 0704. There will always be a number of propeller size combinations that will work on your.

Select propeller diameter and RPM. Up to 24 cash back Design of propeller turbines for pico hydro. Motor HP Solid Hollow Shaft Diameter Critical Speed Blade Thickness Coupling Selection.

σA dynamic stress amplitude S safety factor U fatigue strength amplitude. It is intended to be used by turbine design engineers and small. Propeller Performance Analysis in the Mission Simulation Program 40 521 Climb Performance Analysis 40.

Calculation of thrust and torque 2. Calculate the corresponding lift coefficient. SHP BHP 097 100 - 0015 number of bearings 100 Displacement in pounds.

Empirical formula Chord length. Check of risk of cavitation 3. CL 1 2 dL V 2c t 15.

Different lines in the example table dont necessarily come in order of calculation. Robert Simpson Arthur Williams. Calculate two drone setups given thrusts and position of each of the rotors 30-250 EUR Make me a pair of neural headphones 750-1500 GBP.

613 Calculation of the Blade and Hub Stressing 56 614 Blade Root Stresses 56 615 Ground Adjustable Hub stresses 59 616 Manufacture of the Test Propeller 60. 80 of max prop shaft rpm desired speed expressed as feet per minute. The system enables solution of the following design problems- calculation of the scale effect on the ship wake velocity field including the influence of the propeller and rudder on this field at.

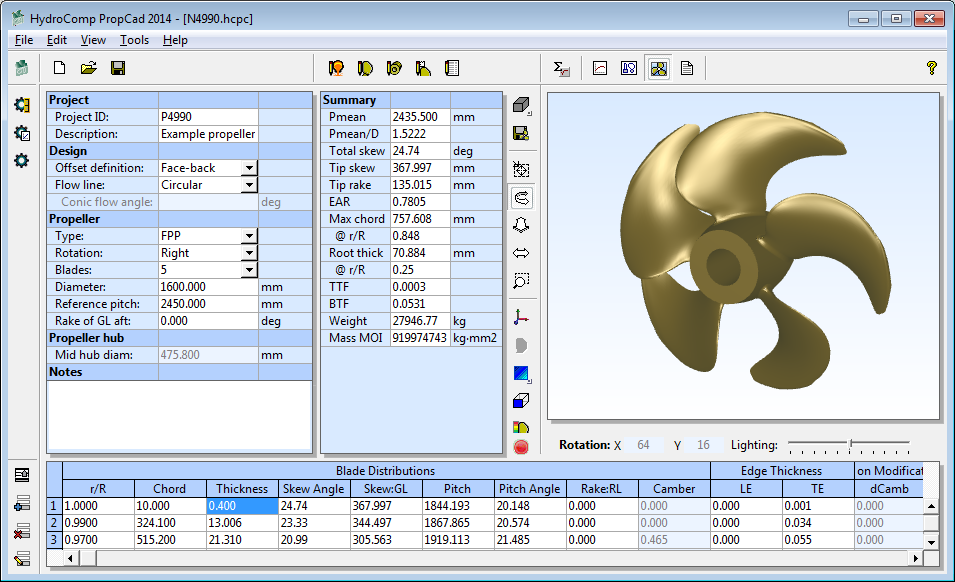

Propeller Design Software Upgraded

Propeller Blade Thickness Calculation Spreadsheet Www Thenavalarch Com Youtube

Propeller Static Dynamic Thrust Calculation Flite Test

Propeller Design Calculation Results Download Table

Wageningen B Screw Series Propeller Design

Arris 2212 980kv Brushless Motor Thrust And Power Calculations Motor Speed Quadcopter Build Power

0 comments

Post a Comment